What Is EDM Sinking?

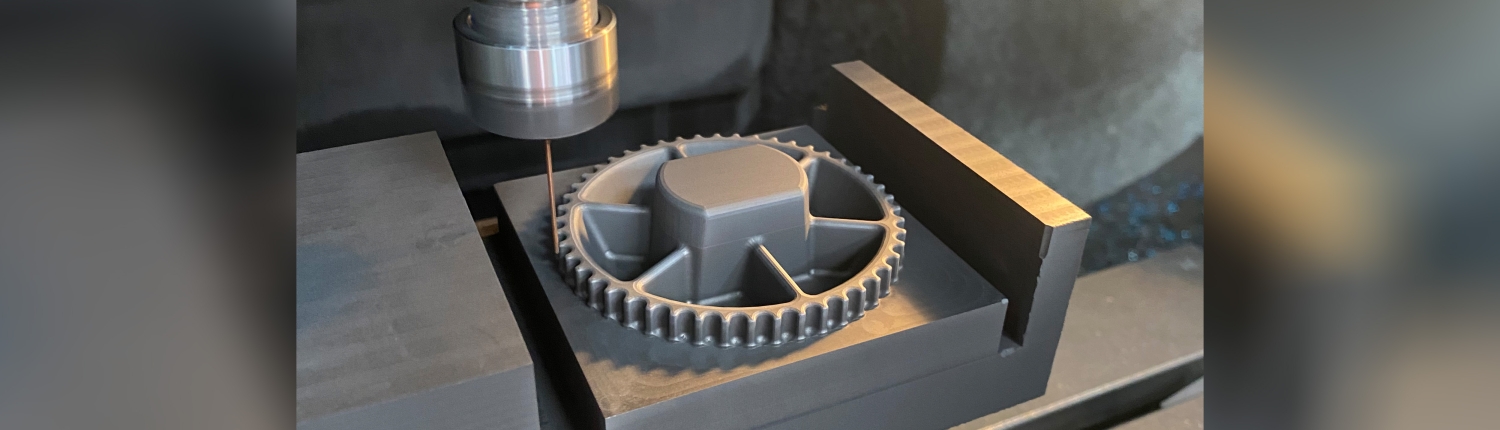

EDM (Electrical Discharge Machining) die sinking, also known as “sinker EDM” or “ram EDM,” is a specialized manufacturing process that uses electrical discharges or sparks to precisely shape or remove material from a workpiece.

This process is primarily used for creating highly detailed and intricate 3D shapes, molds, and cavities in hard and conductive materials.

EDM die sinking is commonly used in tool and die manufacturing, mold making, aerospace, and medical device industries. It is particularly useful for creating intricate shapes, deep cavities, and fine details that are difficult to achieve using conventional machining methods.

Benefits Of EDM Processes

EDM is a non-contact machining process, which means that there is no direct physical interaction between the tool and the workpiece. This lack of contact minimizes wear and tear on cutting tools, allowing EDM to maintain consistent accuracy over extended periods. In contrast, conventional machining methods often require frequent tool replacement and maintenance.

It can also handle a wide range of materials, including those that are exceptionally hard or difficult to machine with conventional methods. Whether you’re working with exotic alloys, hardened steel, or delicate materials like ceramics, EDM can deliver precision results consistently.

What is Wire EDM?

Wire Electrical Discharge Machining (Wire EDM), also known as wire-cut EDM or wire cutting, is a specialized machining process that uses electrical discharges to cut or shape conductive materials with extreme precision. Unlike traditional machining methods, Wire EDM uses a thin, electrically charged wire as the cutting tool. This method is commonly used in industries where intricate and precise cuts are required.

Benefits Of Wire EDM

- High precision: Wire EDM can achieve tight tolerances and produce complex shapes with consistent accuracy.

- Minimal tool wear: Since there is no physical contact between the wire and the workpiece, tool wear is minimal.

- Versatility: It can be used with a wide range of conductive materials.

- Automation: The process is highly automated and controlled by CNC, which ensures repeatability and efficiency.

Broken Tap Extraction

Broken tap extraction EDM, also known as “tap burner” or “tap disintegration,” is a specialized process used to remove broken or sheared taps, drills, or other metallic objects from a workpiece when traditional removal methods, such as drilling or extracting with tools, have failed. The process employs Electrical Discharge Machining (EDM) to disintegrate and remove the broken tool or tap without damaging the underlying workpiece.

We are slightly more case dependant on tap extraction and usually would have to inspect the part before work begins.